Sustainable Inventory Management: 10 Tips For Small Businesses

Customers, regulators, and even employees expect businesses to reduce their environmental impact. Meeting those expectations doesn’t mean you have to turn your business upside-down overnight, though. It’s about taking actionable, manageable, and reasonable steps toward a more eco-friendly future.

Sustainable inventory management is one way to take action. Managing stock levels, sourcing, storage, and distribution profoundly shapes your business’s environmental impact. When all of this is done with the goal of reducing waste, you minimize your ecological footprint without sacrificing customer needs.

These proven sustainable inventory management best practices will help you optimize your back office, improve business operations, and cut costs, all while contributing to a more sustainable future for your business and the planet.

What You'll Learn In This Blog

- The importance of sustainable inventory management

- 10 practical ways to make sustainable inventory management work for your business

- 1. Minimize packaging waste

- 2. Commit to supplier and supply chain transparency

- 3. Optimize inventory with accurate forecasting

- 4. Accurately track inventory in real time

- 5. Adopt circular inventory strategies

- 6. Implement JIT practices

- 7. Choose energy-efficient storage options

- 8. Practice sustainable inventory management with other small businesses

- 9. Train employees on sustainable practices

- 10. Participate in carbon offset initiatives

- How inventory management software supports sustainability

The Importance Of Sustainable Inventory Management

Reduced waste and environmental impact

Arguably the most vital reason to prioritize sustainable inventory management is to minimize harm to the planet we all live on. In addition to lowering operational costs, reducing excessive inventory means less waste ends up in landfills.

It’s estimated that waste associated with inventory accounts for as much as 15% of a company’s greenhouse gas emissions. When you prioritize sustainable inventory management and take steps to mitigate your carbon footprint, everyone can breathe easier.

Meeting evolving customer expectations

Many consumers make purchasing decisions based on how brands align with their values. More than three-quarters of consumers (78%) shared with Nielsen that a sustainable lifestyle is important to them. The majority of consumers are willing to pay more, up to 9.7% more, for sustainably-produced or sourced goods. Sustainable inventory practices help further your company’s eco-friendly goals, bringing sustainability-conscious consumers on board the process.

Reducing costs and improving efficiency

Sustainable inventory management makes good financial sense. Reducing excess inventory, improving demand forecasting, minimizing energy consumption, and optimizing storage all lower bills in a way that boosts sustainability efforts. All of these efforts cross over into improved efficiency, too. You get better outcomes across the board when you’re mindful of balancing inventory levels and utilizing existing resources.

Power Up

Ready to reduce waste? See how simple inventory transformations can protect resources, build community, and support your business’s eco-friendly goals.

10 Practical Ways To Make Sustainable Inventory Management Work For Your Business

1. Minimize packaging waste

Steps to reduce packaging waste are a natural way to introduce sustainable inventory management into your processes. There are multiple ways to do this, including:

- Changing packaging filler from styrofoam to a biodegradable material

- Switching to packages made from recycled materials

- Ordering in bulk from suppliers to reduce the number of packages shipped

- Launching a packaging recycling program for customers

- Carrying more items that use sustainable packaging, no packaging, or recycled materials in your shop

Challenges: Eco-friendly packaging is often more expensive than the alternative. It’s unavoidable to add extra padding and packaging on some products. Furthermore, recycling programs are difficult to implement, both practically and economically.

Solutions: You don’t have to change all your packaging at once. Start with the most practical swaps, maybe opting for mailers made of recycled materials, and work your way up to the more ambitious projects. Remember: many shoppers are willing to pay nearly 10% more for items in sustainable packaging, so any switches will pay off down the line.

2. Commit to supplier and supply chain transparency

Sustainable inventory management practices have roots in good vendor management. Working with the right suppliers puts you on the path to more sustainable inventory practices. This is because ethical sourcing is often tied to sustainability. Chocolate sourced from farms that do not use slave labor is one common issue that affects businesses like gift shops and chocolatiers.

Ways to commit to supply chain transparency and ethical sourcing include:

- Prioritizing local sourcing, as materials travel a much shorter distance when they come from your community

- Choosing Fair Trade Certified or Certified B Corporation vendors over those that do not have any third-party verification of their sustainability practices.

- Conducting regular audits of your supply chain to ensure environmental and fair labor practices are being met.

- Considering adopting Green Procurement buying practices, which center on materials that have a minimal environmental impact. This ensures that businesses make responsible purchasing decisions.

Challenges: Smaller businesses may feel they lack leverage to influence suppliers. There’s also the sheer number of ways to start, deciding what has maximum impact is no easy feat!

Solutions: This is another place to start small. Even choosing one or two suppliers with better credentials is a step in the right direction. Think about prioritizing vendors with values that speak directly to your customer base. For example, an eco-conscious makeup line buys palm oil for its lipstick line from vendors that have obtained the RSPO certification.

3. Optimize inventory with accurate forecasting

A cornerstone of sustainable inventory management is avoiding buying too much in the first place. Stock forecasting uses data analytics and trend analysis to properly tackle demand planning, so you only order what you need while continuing to meet customer demand. Not only does this ensure your business doesn’t contribute to overproduction on a global scale, but it improves inventory management as a whole. A smarter and more accurate ordering process maximizes your space, prevents getting stuck with overstock, and saves money.

Challenges: Inventory forecasting tools take an investment of time and capital, from initial installation to training your team on the tools.

Solution: Look for cloud-based, scalable platforms that fit your current goals and budget but will grow with you as your sustainable inventory management practices expand. Several options will get you started at an affordable price point without risking outgrowing the service you plan to invest in. Commit to training key personnel on the new system so everyone is on board and uses the available tools properly.

Know Exactly What To Buy & When

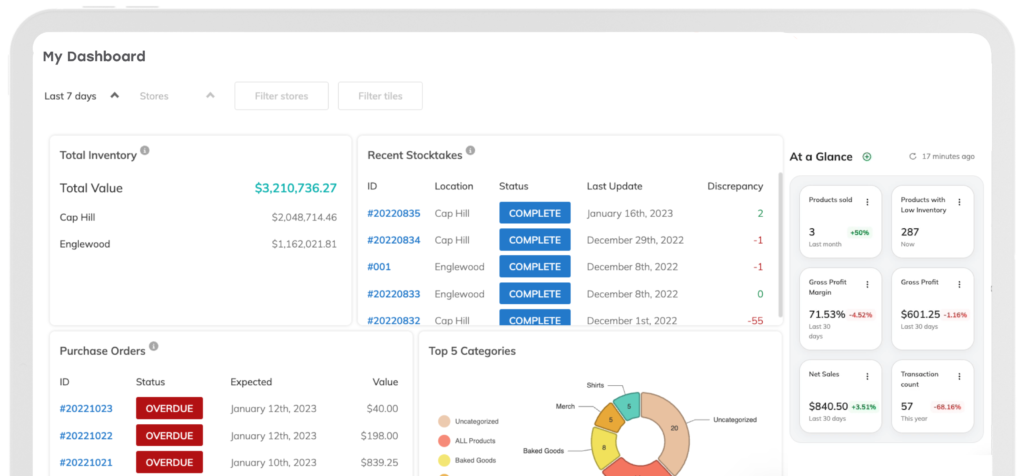

Thrive Inventory shows you historical sales data, real-time stock levels, and demand forecast reports to support your demand planning strategy.

4. Accurately track inventory in real time

Store owners know all too well how much high inventory levels tie up capital. It’s not just a financial issue: unsold merchandise often ends up in landfills, too.

Practices like first-in, first-out (FIFO) rotation, regular stock audits, and markdown management help minimize waste as well. FIFO prioritizes selling what you bring in first so new products don’t sit and take up space. This is especially helpful for trending items, which have a shorter shelf life and are harder to sell once a fad passes.

Stock audits confirm what you already bought so you don’t over-order. Markdown management puts seasonal items and other time-limited products on sale at the right time, so you’re less likely to hold them past the point where it’ll be difficult to sell them, reducing the likelihood of sending products to the trash. That means no more pumpkin spice-flavored coffee in March, and fewer bags of grounds making their way to the landfill.

Challenges: Current inventory management systems don’t provide real-time visibility, leading to frequent excess stock that doesn’t sell.

Solutions: Invest in inventory software with real-time tracking. You’ll get detailed insights into expiring, slow-moving, or trending items. This way, you have a system in place to flag and manage products before it’s too late, while gaining data that helps you order more accurately in the future.

5. Adopt circular inventory strategies

Circular inventory management keeps products, components, and materials in use for as long as possible. Reselling returned items, refurbishment programs, and recycling used products into new stock are all part of this principle.

The environmental impacts of a circular inventory management strategy are significant. For example, extending the life of a clothing item by three months leads to a 5% to 10% reduction in that product’s carbon, water, and waste footprints.

Circular inventory management works especially well for retail stores through the buying back of pre-loved products. These items are refurbished and resold to audiences that care about sustainable consumption. Research from the Harvard Business Review indicates that shoppers are more likely to pay more for items sold as part of a buyback program, and many of those customers value those items more highly. Businesses that want to implement similar initiatives should consider:

- Repair services to bring old items back to life

- Programs that streamline product recycling

- Resale options for used items at a lower price

- Dedicated educational efforts on how to extend product life

Smartwool’s Second Cut Project offers a prime example of this type of program. Instead of throwing old clothing in the trash, customers have the opportunity to send their apparel back for use in Smartwool’s resale program in exchange for a gift card. The program also provides sock recycling kits for socks that are too worn to wear. When customers are rewarded for keeping old merchandise out of landfills, it’s a win-win for all.

Challenges: Reverse logistics are complex. For some retailers, it’s difficult to balance the consistency of materials and demand.

Solutions: Pilot the program on a smaller product line first. Test your process and refine as the program advances. Wait to expand as you refine and perfect your processes. Make sure you also use tools that support reverse logistics so these items are properly tracked, managed, and tagged separately from new stock.

6. Implement JIT practices

Just-in-time inventory involves ordering and receiving goods only as they are needed, minimizing excess stock. You’ll schedule raw materials to arrive as production begins, but not any sooner. This way, your inventory levels are just right to meet customer demand.

One common way to incorporate JIT practices is to offer made-to-order options. Many small batch coffee roasters, for example, only roast and ship when an order is placed. This ensures freshness and eliminates waste.

Challenges: JIT leaves you vulnerable to supply chain disruptions. It also creates a dependence on your current suppliers.

Solutions: Keep close relationships with key suppliers. Don’t limit yourself to just one vendor, either, so you always have a backup on hand if there are supply chain issues. Invest in reliable forecasting systems as well to prevent disruptions.

7. Choose energy-efficient storage options

Warehouses and storage facilities consume significant amounts of energy, increasing greenhouse gas emissions, affecting natural resources, and leaving a large environmental footprint. Prioritizing energy efficiency by switching to LED lighting or efficient equipment is a great effort to take toward improved warehouse sustainability. Investing in technology like solar panels is the right move for some businesses, too.

Energy-efficient improvements are good for your wallet and the planet. Warehousing costs in the U.S. take up approximately 10% of a company’s revenue. Owners face high costs because of significant energy consumption, whether high power costs are passed off in rental costs or the business owns (and pays the bills on) its storage space outright.

Challenges: If you own your warehousing facility, upfront costs are high for these upgrades. If you rent space in a warehouse, some of these factors are out of your control.

Solutions: If you rent, find a fulfillment center that’s committed to running on 100% renewable energy. When you make the switch, inform your customers so they know the efforts you’re taking to manage a more sustainable warehouse. If you own your storage space, many programs offer rebates on energy-efficient lighting and other equipment. Some of these rebate programs cover a majority of the cost you lay out.

8. Practice sustainable inventory management with other small businesses

Collaboration over competition! Band together to achieve your sustainable inventory management goals. Pooling resources with other local or like-minded businesses reduces waste, cuts costs, and creates an inspiring story for your marketing and messaging. Sharing warehouse space or splitting last mile logistics are two practical ways to pursue this kind of partnership.

Challenges: Businesses may struggle to find appropriate partners to collaborate with. Successful partnerships require open communication to ensure both businesses are able to meet their sustainable inventory management needs.

Solution: Prioritize partners with similar missions and a demonstrated record of practicing similar business values. Start off on the right foot with a transparent line of communication and set data-based goals together. Set measurable benchmarks for your partnership and make a point to regularly check in and evaluate your progress.

9. Train employees on sustainable practices

Your employees are essential to successfully adopting sustainable inventory practices. Conduct regular training on waste reduction, proper stock rotation, and energy conservation. Create clear sustainability policies and inventory management practices so your employees have a strong understanding of their role.

Challenges: Your employees are busy, and sustainability initiatives add something else to their schedules.

Solutions: Make sustainability an integral part of your business and brand instead of another checklist item. When sustainability best practices are folded into standard operations, it’s not likely to be neglected and will simply become a natural part of a day’s work. And in many cases, like JIT ordering, forecasting, and markdowns management, your staff is already doing the work.

10. Participate in carbon offset initiatives

Carbon offset programs are a meaningful way to improve your inventory sustainability without making major structural changes in your business. These programs allow you to invest in eco-friendly projects elsewhere, effectively “offsetting” your carbon emissions. Investing in reforestation or generating renewable energy via wind farms are two examples of projects funded by carbon offset initiatives.

Challenges: Finding a trustworthy partner is no small task. Only participating in carbon offset initiatives also opens up criticism that your business isn’t doing enough for sustainable inventory management. You don’t want to appear as if you’re deflecting responsibility by throwing money at the problem instead of making systemic changes.

Solutions: Use programs like the Climate Action Reserve, TerraPass, Carbon Fund, and Gold Standard, which are highly rated and have a long track record of success and transparency. Continue to look for other ways to reduce waste and improve inventory sustainability.

How Inventory Management Software Supports Sustainability

Good inventory management software is a cornerstone of sustainable practices. The right system:

- Centralizes inventory data: Eliminate unnecessary stock movements and see a real-time view of what you have. Inventory turnover ratio, packaging waste utilization rates, and storage capacity utilization are all trackable and are key metrics to monitor as you pursue sustainable inventory management practices.

- Reduces manual processes and paperwork: Digital workflows cut down on printed paperwork, save staff time, and reduce human errors that lead to waste. Changes as simple as introducing barcodes decrease human error by more than 40%.

- Is cloud-based: Cloud-based systems are more efficient since they are accessible from anywhere, including off-site storage. Everyone works from the same body of data with real time inventory levels, decreasing errors and improving tracking efforts that are essential to many inventory sustainability efforts.

- Uses machine learning for forecasting: AI-driven systems help forecast demand, reducing the likelihood of surplus and stockouts while assisting busy staff as they manage inventory.

Automate Inventory Sustainability

Thrive Inventory has a suite of tools designed to help businesses achieve their sustainability goals. From restocking levels to component level tracking, Thrive Inventory empowers stores to repurpose surplus stock, identify special promotions, and tighten their order management strategy.

Sustainable Inventory Management Starts At The Core Of Your Business

Sustainable inventory management is good for the planet and for your brand. Customers want to support eco-friendly businesses. This competitive edge is enough to bring in new customers and encourage existing ones to return. So many of the initiatives that support people and planet prioritize resource efficiency, creating a more resilient company overall as well.

The time to act on sustainable business operations is now. Implementing even a few of these eco-friendly inventory practices sets you on the path toward environmental sustainability. By aligning your inventory practices and business strategy with sustainability goals, you’ll future-proof your operations and contribute meaningfully to the global effort to protect our environment.

The Newsletter For Small Businesses

Weekly expert insights, industry trends, and inspiring stories designed to help you run your business with confidence.

The Only Inventory System That Actually Helps You Run A Healthy Business

Thousands of customers all over the world use Thrive Inventory to run a healthy business.

Thrive Inventory gives you control over all your inventory, sales channels, and metrics, allowing you to make the right decisions at the right time.

Keep Reading

The Newsletter For Small Businesses

Weekly expert insights, industry trends, and inspiring stories designed to help you run your business with confidence.

Try Thrive Inventory For Free

Add Thrive Inventory to your business and maximize your potential. With powerful and easy-to-use products,

it’s time to take control of your business and see what you can do with Thrive Inventory.