Understanding Demand Planning

From marketing to surveys, there are several ways to keep up with what your customers want and tailor your offerings to their needs. Demand planning ensures you deliver. In this article, you’ll learn about demand planning and why this process is essential for increasing your sales and keeping shoppers happy.

What Is Demand Planning?

Demand planning is a strategic supply chain management process. It involves forecasting future demand for products or services based on historical data, market trends, and other relevant factors. During this process, you anticipate customer needs to optimize your inventory levels and improve production or ordering schedules.

Demand planning vs. supply planning

Supply chain management consists of demand planning and its counterpart, supply planning. Below are some key differences between these processes.

- Objectives: Demand planning focuses on forecasting future customer demand for precise inventory management. Supply planning ensures you have the resources and production capacity to meet forecasted demand.

- Key components: Demand planning involves data analysis and collaboration with sales and marketing to understand customer preferences and buying trends. Supply planning focuses on managing inventory and maintaining a steady flow of raw materials.

- Flexibility: With demand planning, you need to adapt quickly to changes in customer desires and market dynamics. Your supply plan should then be strategic to keep pace with evolving customer needs.

These two concepts aren’t mutually exclusive, but often go hand in hand. Let’s say an artisan cheese shop reviews forecast data to identify high demand seasons. This information then influences more accurate supply planning, so the shop doesn’t have to worry about excess inventory spoiling when sales are lower.

Why Is Demand Planning Important?

Avoid stockouts

Stockouts happen when demand exceeds available inventory. This leads to lost sales opportunities and may damage customer relationships. However, by carrying optimal inventory levels, you can minimize stockouts.

Power Up

Learn why stockouts happen and six tips you can implement to avoid them.

Reduce excess inventory

Surplus inventory ties up capital, takes up precious storage space, and increases the risk of product obsolescence. Demand planning reduces excess inventory by giving you a better idea of how much of each item you should keep on hand. Accurately anticipating customer demand leads to optimal inventory management practices and much lower carrying costs.

Laurie Carter, the owner of Apples to Oranges, learned this firsthand and shared her experience on The Power Up Podcast. When she first opened her craft shop in Silverton, Oregon, Carter said she didn’t fully understand the need for calculating demand, which turned out to be a costly oversight.

“I overbought at the beginning, and that was a mistake because it took a while for people to even realize that I was there,” she said.

Power Up

Stuck with excess inventory? Here are five ways you can still profit. Plus, strategies to keep your inventory levels in check.

Cut costs

Proper demand planning gives you better control over resource management. Demand forecasting helps you adjust production schedules to match expected sales volumes. This ensures you get the most of your resources, including raw materials, labor, and equipment. This, in turn, reduces waste and minimizes production costs.

Refine order management

Plan and schedule your product orders more effectively to create a better order management process as you nail down order quantities, timing, and distribution channels to meet customer needs.

Once she understood her product demand, Carter shifted her inventory strategy to adjust for fluctuations in demand and reduce excess inventory.

“I gave away yarn. I had big sales on yarn, and I cut way back to the yarns that I had experience with that I knew would sell well,” she shared.

This strategic adjustment allowed her to adjust inventory levels and focus on stocking items that were in high demand.

Optimize sales

Demand planning gives you key insights into customer buying behaviors and market trends. This information is invaluable for developing targeted marketing and sales strategies that ultimately increase your sales opportunities.

Improve customer satisfaction

Accurately forecasting demand and maintaining optimal inventory levels allows you to decrease lead times and reduce backorders. This ensures that products are available when your customers want them so they won’t shop somewhere else.

Since adjusting her product strategy, Carter honed her approach to better meet customer demand. While conducting customer research, she discovered that shoppers in the Silverton area needed more options for art supplies. Carter expanded her product offerings to meet that demand, a decision that significantly enhanced her store’s appeal to new customers and kept existing ones happy.

Types Of Businesses That Should Practice Demand Planning

Retail

Retailers use demand planning to forecast sales volumes for various products, anticipate seasonal trends, and adjust inventory levels accordingly.

During peak shopping seasons, retailers use demand planning to ensure they have sufficient stock of popular items. They also use demand planning to optimize product assortment, pricing strategies, and promotional activities based on customer preferences.

Food and beverage

Demand planning is crucial for food and beverage companies, especially those managing perishable goods. Good demand forecasting means scheduling raw materials and ingredients to arrive in alignment with production needs. This minimizes spoilage and waste.

For example, during holidays like Memorial Day Weekend, a brewery should use demand planning to ramp up beer production to meet increased consumer demand. This ensures optimal inventory levels and that products are fresh when customers purchase them.

Seasonal

Businesses operating in seasonal industries, like skiing and snowboarding shops, rely heavily on demand planning to adapt in the off-season. Demand planning forecasts customers’ product or service needs based on variations such as holidays, special events, and the weather. Accurately predicting demand makes it easy to adjust inventory, staffing, and marketing strategies.

A local pumpkin patch, for example, might use demand planning to anticipate customer demand for the fall season. Using historical sales data, the farm forecasts sales volume and adjusts how much is planted or brought in accordingly. This process also ensures the farm is appropriately staffed and well stocked with inventory for its gift shop.

Manufacturers

Demand planning helps manufacturers anticipate and optimize production schedules. As a part of supply chain management, this process is especially useful in identifying potential bottlenecks or disruptions. From there, they proactively address these issues before they become significant problems.

This process provides insights for implementing contingency plans and diversifying suppliers. Demand planning also minimizes the risk of overproduction or underproduction so products reach customers in a timely manner.

Challenges Of Demand Planning And How To Solve For Them

Shifting market trends

Economic conditions, consumer preferences, and industry dynamics all influence market trends, and they sometimes shift as quickly as a social media video goes viral. Failing to accurately predict these trends leads to off-kilter demand forecasts, resulting in overproducing or underproducing goods.

To address this challenge, it’s important to invest in market research and data analytics tools. These platforms remove the guesswork from forecasting and predicting what customers want.

Niche business models

Selling niche products or services means you have limited historical data or market insights to draw from, making it difficult to forecast demand accurately. As a solution, instead of relying solely on past trends, focus on gathering as much data as possible about your target market and customer preferences. Collaborating with industry experts and leveraging market research also provides valuable insights for refining demand forecasts.

Changing customer behavior

The way customers shop and make purchase decisions is constantly evolving. A decade or two ago, consumers relied more on traditional advertising channels and then went to the store to make their purchases. Today, internet searching, influencer marketing, and e-commerce take center stage.

To tackle this challenge, consider segmenting customers based on demographics, past behavior, and purchasing patterns. This approach identifies emerging trends, anticipates shifts in consumer behavior before they occur, and offers a customized shopping experience many customers have come to expect.

Incomplete sales and inventory reporting

Without access to reliable data, a business struggles to make informed plans. Poor reporting practices lead to miscalculating demand, which results in inventory shortages or excess stock.

It’s important to invest in robust sales and inventory management systems. Implement integrated demand planning software solutions and conduct regular audits to ensure precise and timely reporting, crucial for optimizing the demand planning process.

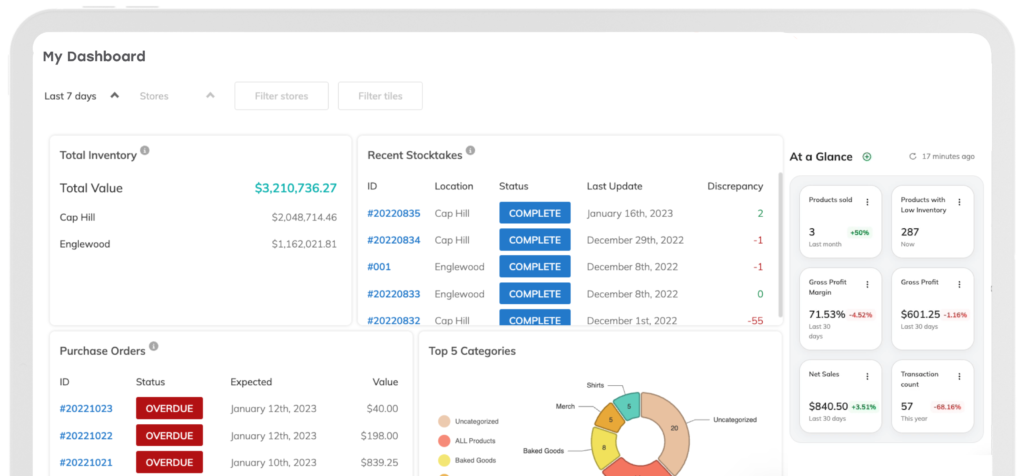

Increase Sales And Inventory Visibility With Thrive Inventory

Know exactly what’s coming in and out of your store so you can make better business decisions. Thrive Inventory shows you historical sales data, real-time stock levels, and demand forecast reports to support your demand planning strategy.

Outdated or inefficient technology systems

Dated technology or manual processes hinder access to data about your customers. Using cloud-based solutions and implementing advanced analytics tools streamlines data collection processes and improves demand forecast accuracy.

How To Select A Demand Planning Method

Quantitative demand planning methods

Quantitative demand planning dives into historical data and inventory levels. Below are several quantitative methods.

- Sales reports and historical data: With this method, you’ll examine sales data to identify trends and forecast future demand. This approach assumes that future sales will follow similar trends. For example, a clothing company might analyze sales data from the last five winters to predict upcoming demand for coats and order accordingly.

- Sales per category: Analyze sales data to understand which categories perform best. It helps you allocate inventory based on the demand for each category. As a simple example, if you run a neighborhood corner store, you’ll track sales data for categories like chips, soft drinks, and dairy products. If your data shows that chips have consistently high sales, you’ll then plan to stock more of those snacks and possibly introduce new items into that category.

- Sell-through rates: This is the percentage of inventory sold within a specific period compared to the amount of inventory received. It helps you understand how quickly products are selling and make decisions about reordering popular products or offering discounts to help them move faster. Consider, for example, a candle shop notices its apple crisp candles have a high sell-through rate. With this information, the shop knows stocking more is an effective inventory strategy and may consider increasing stock levels. On the other hand, if the shop’s blueberry pie candles have a low sell-through rate, the shop might run a 50% off sale to make room for other items.

- Turnover ratio: This measures how often inventory is sold and replaced over a given period. A higher turnover rate indicates that products are selling quickly, which is generally a sign of good inventory management and demand forecasting. A bookstore, for example, might calculate the inventory turnover ratio for its top five best-selling paperbacks. If a particular book has a high turnover rate, demand planners ensure that the book is frequently restocked to meet continuous demand.

- Excess inventory: Managing excess inventory is crucial to free up capital and storage space for products with higher demand. This method involves identifying inventory that remains unsold for a long period. A toy store, for example, finds that Spider-man action figures haven’t sold well for several months, leading to excess inventory. The store then realizes customer demand for these items isn’t as strong as anticipated and significantly reduces the number of Spider-man toys it orders.

Free Template: Inventory Formulas

Plug and chug with Thrive Inventory’s formulas spreadsheet so you can manage your business with accuracy.

Qualitative demand planning methods

Qualitative demand planning methods rely on assessments and observations rather than statistical data. They’re particularly useful when you’re working with limited or unreliable historical data. Here are some qualitative methods.

- Trend analysis: This focuses on noticing and examining patterns or shifts in customer behavior, the market, or social dynamics to anticipate future demand. Understanding changes in preferences, lifestyles, and cultural influences is key to trend analysis. A local coffee shop, for example, might notice a growing interest in beverages made with oat milk. Based on this observation, the shop anticipates increased demand for milk alternatives and adjusts its menu and inventory accordingly.

- Customer research: Surveys, focus groups, and interviews are great ways to make inventory decisions based on customers’ preferences and purchasing behaviors. Let’s say that you own a bakery. During winter, ask customers what types of treats they enjoy during the summer. Based on the responses you receive, it’s easy to stock up on ingredients and products you expect will be high in demand.

- Market research: This method focuses on analyzing broader market trends, your competition, and economic factors that impact demand. It involves consulting with experts, reading reports, or conducting your own focus group. For example, a local bookstore might consult with publishing industry experts to learn about upcoming book trends and genres that are gaining popularity. The store might also gather market reports on the latest reading habits and preferences in their target market, such as young adult readers or self-help book aficionados.

Mixed demand planning methods

Mixed demand planning methods combine quantitative and qualitative approaches to create a thorough and balanced strategy for demand forecasting. While quantitative methods provide data-driven predictions, qualitative methods add context, capturing what numbers alone can’t fully explain.

A mixed-methods approach gives you more agility in finding ways to stay on top of market changes. It also enhances the accuracy of your predictions. Cross-verifying quantitative forecasts with qualitative assessments reveal any discrepancies, so you’re able to adjust your forecast accordingly.

How To Implement A Demand Planning Strategy

- Set your forecasting period: There are several ways to approach this step. Short-term demand forecasting involves planning for the next three to 12 months. If you tend to frequently adjust your product offerings, this approach helps you quickly respond to changes in customer demand. Long-term demand forecasting looks from one to four years down the line. This approach is geared more toward decision-making for consistent growth.

- Follow relevant shifts: Seasons, weather, and popular local events are great indicators of how customer demand might fluctuate. For example, if you own a gardening supply store, you anticipate higher demand for tools and plants during the spring and summer months. Similarly, a boutique plans to update their collection with new product offerings with each upcoming season . Track these factors to match your inventory levels to expected changes in customer demand.

- Align with your marketing strategy: Make sure your demand planning is aligned with your marketing activities. For example, if your bakery plans a marketing campaign for a new line of cupcakes, it’s a good idea to expect more customers who want to try your new treats. Incorporate this spike into your demand forecast to ensure you have sufficient inventory to meet customer needs.

- Revisit and adjust regularly: Demand planning isn’t a one-time activity. Regularly revisit and adjust forecasts to reflect the latest data and market conditions. Create a feedback loop where you compare actual sales information to your forecasts to find areas where you over- or underestimated demand.

Thrive Inventory offers comprehensive data analysis and forecasting tools that help you generate financial calculations, identify trends, and adjust projections in real time. This makes it easy to track and review your business’s sales information.

Sell-through rates and category sales are readily available to analyze, providing valuable insights into product performance and customer preferences. With Thrive Inventory, you’ll efficiently monitor which products are selling well and which ones are lagging, allowing you to make the best data-driven decisions in your demand planning process.

What Happens If You Get It Wrong? Handling Common Inventory Scenarios

How to handle stockouts

In the case of a stockout, it’s important to keep customers informed about delays and provide estimated restock dates. Offer backorder options, and suggest alternatives if possible. Behind the scenes, focus on vendor management to expedite shipments or find alternative suppliers to quickly restock. In addition to better demand planning, maintain a safety stock of high-demand items so you have a cushion against unexpected spikes in demand.

How to handle excess inventory

To manage and reduce excess inventory, look at your data to identify slow-moving items and understand why these products are not selling. Then, consider implementing promotions like discounts, bundles, or special offers to move the excess stock more quickly. You might also consider diversifying your sales channels by selling through online marketplaces or wholesaling.

Keep Your Inventory Levels In Check With Thrive Inventory

For easy tracking, Thrive Inventory consolidates all your inventory data in one place. Know what you have in stock and how you need to adjust your inventory for optimal performance. With Thrive Inventory, you greatly reduce the risk of stockouts and excess inventory. Thrive Inventory management tools sync with your POS system and e-commerce store so your stock counts are up to date. You’ll know exactly how much inventory you have on hand at all times.

Demand Planning: The Most Effective Way To Chart Your Company’s Course

Effective demand planning is key for maintaining the right balance of inventory, minimizing costs, and ensuring customer satisfaction. Start with an understanding of your inventory, and make customer and market data your foundation to get the most accurate demand forecasts. By capitalizing on this information, you’ll focus on growing your business and keep your customers happy with products that are readily available when they need them.

The Newsletter For Small Businesses

Weekly expert insights, industry trends, and inspiring stories designed to help you run your business with confidence.

The Only Inventory System That Actually Helps You Run A Healthy Business

Thousands of customers all over the world use Thrive Inventory to run a healthy business.

Thrive Inventory gives you control over all your inventory, sales channels, and metrics, allowing you to make the right decisions at the right time.

Keep Reading

The Newsletter For Small Businesses

Weekly expert insights, industry trends, and inspiring stories designed to help you run your business with confidence.

Try Thrive Inventory For Free

Add Thrive Inventory to your business and maximize your potential. With powerful and easy-to-use products, it’s time to take control of

your business and see what you can do with Thrive.