Stockouts: What They Are And How To Prevent Them

Think of a time when you wanted to buy a product. You knew that a particular store or website sold the item. However, you arrived only to find that part of the shelf empty, or you saw that bright red “out of stock” marker on the website. Then, you headed somewhere else to shop.

You certainly don’t want your customers to experience this frustration with your business. Avoiding this is all about keeping your products in stock with proper inventory management approaches. In this article, you’ll learn all about inventory stockouts, along with ways to prevent stockouts from happening.

What Is A Stockout?

Stockout is when a business runs out of inventory for one or multiple products. When a stockout occurs, a business can’t sell or ship those products to customers.

Stockouts’ most obvious negative impact is lost sales, but that’s not all. Going out of stock can lead to a negative brand reputation with customers, especially if they’re left wondering when the item will be available again.

Additionally, if an item is incorrectly listed as in stock on the business’s website, customers might buy the item and need to be refunded. These stockout costs can quickly add up as more customers try to purchase the item.

Stockout Vs. Shortage - What's The Difference?

Stockouts and shortages can be consequences of similar issues, such as problems during the ordering process or a sudden increase in customer demand. However, these terms are a bit different. A retail shortage occurs when there’s limited inventory for a product. A stockout, on the other hand, happens when an item is entirely unavailable.

What Causes Stockouts?

1. Inaccurate stock counts

The need to properly track inventory is essential to avoid stockouts. Whether the result of human error or some inventory went missing (mistakes you’re way less likely to run into when you use an inventory management system), inaccurate stock counts can easily lead to stockouts. Your books might say one thing, but your actual count might be different, leaving you with less inventory than you thought.

No More Manual Inventory Counts

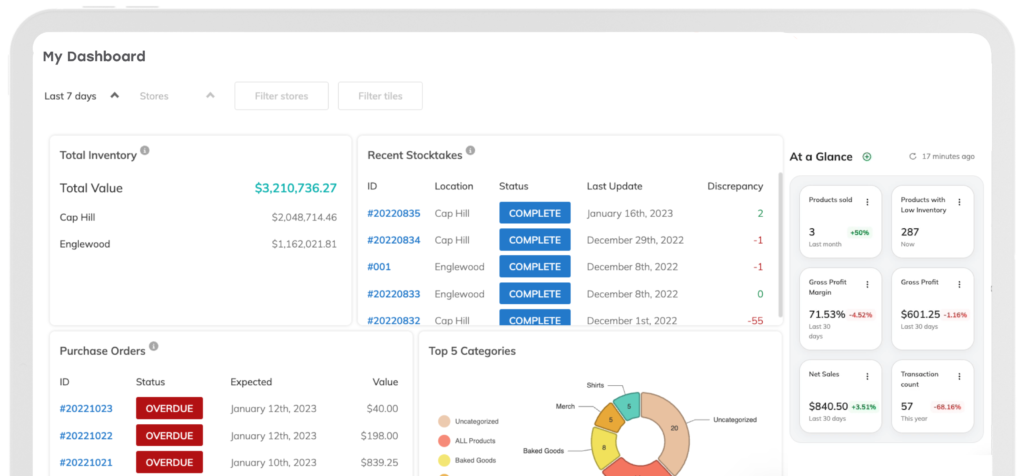

You need to know exactly what you have on your shelves and in your back office at any given point in time. Thrive Inventory is designed to handle all your SKUs and simplify cycle counts with our Stocktake feature.

2. Supply chain issues

Major production or shipping delays can prevent inventory items from arriving when your business needs them. If the problem gets out of hand, supply chain issues can quickly result in a stockout.

Consider this issue during the COVID-19 pandemic, especially its first two years. Travel restrictions, stay-at-home orders, and labor shortages all disrupted supply chains around the globe. In fact, 38 percent of small businesses experienced supply chain issues related to the pandemic. The lingering effects of these supply chain issues can still be felt today as shortages remain common.

3. Changes in demand

A sudden increase in customer demand is one of the most common causes of stockouts. If consumers suddenly flock to a certain product, that can quickly disrupt your normal ordering processes and your inventory supplies.

For example, a multipurpose cleaner called The Pink Stuff went viral on TikTok in 2020 and 2021. As more videos circulated of the cleaner removing tough stains, demand for The Pink Stuff rose sharply and dramatically. As a result, it sold out repeatedly across the U.S.

4. Poor reordering strategy

Knowing when to place inventory orders is among the best ways to prevent stockouts. If you forget to reorder products or you wait until your stock counts are near zero, you risk a stockout. This also make issues like increased demand and supply chain disruptions more challenging. You might be unable to quickly recover or respond to these issues without running out of stock.

[Free Kit] Take Control Of Your Inventory

Stockouts, poor organization, excess inventory… it doesn’t have to be that way. Download our free inventory management kit.

5. Financial issues

Budgeting controls just about every part of a successful business, including inventory. Think about it like this: Let’s say you’ve overspent in other areas, such as a redecorating project for your shop or the company holiday party. That might mean you need to cut back on restocking your inventory. In that case, you could be pushing your small business closer to a stockout.

Even if your business didn’t bring in as much profit as you expected, avoiding stockouts should be a priority. After all, limited funds for ordering more inventory can leave you without enough products for the next period and cause a stockout. Finding some money to spend now can help you avoid major stockout costs later. One way to do this is to consider dropping a less popular product and using that budget to order more of a popular product.

How Do Stockouts And Shortages Affect Your Business?

- Reduces sales. Your business generates revenue from the products it sells, so with less inventory, your business can make less money. A stockout can negatively impact your business’s profits and result in lost sales since customers simply can’t buy your most reliable products.

- Upsets customers. If a customer sees that your business sells a certain product, they expect that product to be in stock. The inconvenience of shopping around for products only to find that they’re out of stock can be upsetting for customers. Shoppers also might not be too happy about having to cancel their orders because they later learn an item is out of stock. This decreased customer satisfaction can contribute to issues with customer retention down the line.

- Impacts brand loyalty. A stockout could send a customer directly to one of your competitors. After all, if customers can’t find the items they’re looking for with your business, they’ll often look elsewhere for what they need. This has long-term effects as well. Going forward, a customer might remember they found what they needed with another business. They might shop there without first checking whether your business is stocking the product.

- Increases costs of replenishing products. If your business experiences a stockout, you and your employees might rush to resupply the out-of-stock items. However, requesting that suppliers fulfill high-priority orders can be costly. Express manufacturing and delivery fees are often much more expensive than fulfilling standard orders. The increased pressure on suppliers could also negatively affect your relationship with them.

How To Manage Customers During A Stockout

Stockouts can be a major inconvenience for your customers. As a business owner who values customer satisfaction, you should prioritize accommodating customers who can’t get the products they want to purchase.

To help counter a stockout’s negative impacts, you can offer customers alternative products that could also meet their needs. You can also offer discounts on these products to encourage these customers to continue shopping with you.

There might be a case where a customer has their sights set on only the product currently out of stock. Here, you can offer to take down the customer’s contact information and notify them when the product is back in stock. You can also ask for their mailing address so you can ship the product directly to them as soon as you receive it.

Tools That Can Help You Manage A Stockout

- Inventory management software. With inventory management software, you can accurately track your business’s inventory, though manual counts will remain important for double-checking. Inventory management systems are designed to counter human error and help you avoid stockouts or address related issues. You can also pull inventory data to see when you should buy more and when your inventory supplies started decreasing.

- Stock forecast reporting. Inventory forecasting is the practice of using historical sales data and trends to help you gauge future demand. Strategic inventory forecasting is one of the best ways to avoid stockouts.

- Third-party logistics. A third-party logistics (3PL) provider is a company that handles businesses’ supply chain operations to ensure products reach customers in a timely manner. These providers handle the storing, packing, and delivery processes while working with fulfillment centers. This way, there’s less your business has to manage while getting items back in stock.

Never Run Out Of Stock Again With Thrive Inventory

With Thrive Inventory you can bring together all of your different sales channels into our software making stock level management easy. With Alerts, you’ll know exactly what’s happening with all of your products at any set point in time, even if they are sold on different channels.

6 Tips For Avoiding A Stockout

1. Conduct regular cycle counts

Oftentimes, stockouts start with inaccuracies in inventory counts. Conducting cycle counts can help you track your inventory across product groups and account for minor instances of human error.

Cycle counts are frequent, regular checks of your business’s inventory. During a cycle count, you’ll look at the number of products that were in stock at the beginning of a period. From there, you’ll tally up the number of those products you’ve stocked and look at how many products you’ve sold since then. You can compare this number with the stock count your inventory management system shows. With this information in hand, you can compare it to the low stock alerts on your website to ensure the figures match.

Power Up

Learn how to complete an inventory cycle count step by step in our complete Cycle Count Guide.

2. Set aside safety stock

Safety stock is extra inventory you keep on hand in case a product’s supply starts running low. Safety stock serves as a buffer in the case of an unexpected increase in customer demand, without buying too much inventory.

When you set safety stock aside, you don’t make this inventory publicly available, but you still add it to your inventory management system. The idea behind safety stock is for these products to be an emergency supply of inventory that you pull out only if necessary. As such, safety stock shouldn’t be part of your inventory count – it’s your fallback if your count reaches zero. Keep in mind not to order more than you can realistically sell, though, because this could lead to excess inventory issues.

3. Evaluate reorder levels quarterly

Reviewing your reorder levels quarterly can help you set low stock alerts at the best times for keeping up with customer demand. For example, two months ago, you might have been safe ordering more tablet chargers when your inventory count reached 75 chargers. Now that your customer base has expanded, the inventory data may indicate you might need to trigger reorder levels when your inventory reaches 100 chargers.

With this approach, you can ensure you have enough supplies to last until the next order arrives. Also, if you know when items will be reordered, you can tell customers when to try shopping again for their favorite products.

Thrive Inventory PAR Levels & Alerts

Streamline re-ordering and know before you run low with minimum and maximum stock levels and custom alerts so you always have just enough.

4. Use backup suppliers

If a supplier is facing production or shipping issues, it can be useful to have another supplier on hand. This way, you can get the inventory you need without creating too much of a gap in your inventory. You can incorporate finding and vetting out backup suppliers into your vendor management process so that, when you need them, they’re ready to help.

5. Use FIFO

First-in, first-out (FIFO) is an inventory management method in which the items you purchase first are the ones you sell first. With this approach, you can make sure you’re not hoarding excess inventory on your shelves. This method works especially well with perishable inventory, as it helps you sell items before they expire. FIFO can help you toss out fewer items and run out of stock less often.

6. Implement inventory forecasting

An accurate forecast based on inventory data helps you determine which products to stock up on so you can keep up with customer demand shifts. For example, let’s say you know that customers often purchase your vanilla bean-scented lotions as gifts. In that case, you might want to add more of these items to your inventory as the holiday season approaches.

7. Store inventory properly

Staying organized is necessary to properly track inventory and monitor inventory levels. This way, you can step in before a stockout is even in the cards. Develop a system for inventory storage and ensure all employees adhere to the system to ensure accurate stock counts going forward.

Staying On Top Of The Basics

Inventory is among the foundational elements of your business – it’s a big part of what keeps customers coming back to you. That’s why it’s important to keep enough inventory on your shelves for all your customers, whether through setting aside safety stock, using the FIFO method, or more frequent stock evaluation. With the right strategies and tools in place, you can prevent stockouts, increase customer satisfaction, and keep your profits rolling in.

The Newsletter For Small Businesses

Weekly expert insights, industry trends, and inspiring stories designed to help you run your business with confidence.

The Only Inventory System That Actually Helps You Run A Healthy Business

Thousands of customers all over the world use Thrive Inventory to run a healthy business.

Thrive Inventory gives you control over all your inventory, sales channels, and metrics, allowing you to make the right decisions at the right time.

Keep Reading

The Newsletter For Small Businesses

Weekly expert insights, industry trends, and inspiring stories designed to help you run your business with confidence.

Try Thrive Inventory For Free

Add Thrive Inventory to your business and maximize your potential. With powerful and easy-to-use products, it’s time to take control of

your business and see what you can do with Thrive.