Beyond Checkout: Barcode Scanners And Their Role In Inventory Management

Barcode scanners are essential for more than just completing customer transactions at the point of sale — they’re a must for efficient and accurate inventory management. Below, we’ll get into how barcode scanners contribute to streamlined stock control and the ways to incorporate them into your inventory management processes.

What Is A Barcode Scanner?

A barcode scanner analyzes and interprets barcodes, those black-and-white striped codes you see on product packaging. The device uses a laser scanner or camera to capture the pattern of bars and spaces, translating this data into readable information, typically a code of numbers or letters that identify that particular product. In an instant, that data is then sent to your computer system.

Barcode scanners optimize your back office by simplifying and accelerating the process of tracking inventory levels, managing product locations, and updating stock records. These scanners ensure items are accurately accounted for, from the moment they’re entered into your system. As products move within your warehouse, barcode scanners also help you correctly track inventory, reducing manual errors.

Information a barcode contains

Barcodes tell you more than just the product name. When scanning a barcode, you’ll get access to all of the details you need for thorough inventory tracking, including:

- Price: Keep your records up to date with current product cost information.

- Weight: Facilitate weight-based inventory management.

- Manufacturer: Note the name of the manufacturer where the product originated.

- Manufacturing date: Easily see when the product was made.

- Expiration date (if applicable): Monitor products that are set to expire or spoil.

Types of barcodes

There are two main types of barcodes. The type that likely comes to mind for most people is one-dimensional barcodes, also known as 1D or linear barcodes. This kind of barcode consists of a series of vertical lines and spaces of varying widths that encode information in a one-dimensional format. They are often used to represent stock keeping units (SKUs), which are unique identifiers assigned to each product.

Two dimensional barcodes (2D) offer a more advanced way of encoding data. They use patterns of squares, dots, or other shapes arranged in a two-dimensional grid that allow them to store much more information. QR codes are a popular type of 2D barcode that store alphanumeric data, URLs, or multimedia information.

Barcodes vs. SKUs

While SKUs provide a specific code to identify products internally, barcodes encode these SKUs into a scannable format. When a barcode is scanned, it translates the SKU into a readable format that helps retrieve product details and update inventory records.

Benefits Of Using A Barcode Scanner For Inventory Management

Speed up the inventory tracking process

Scanning a barcode allows you to quickly update and check on stock levels much faster than manual data entry. When you scan a barcode, the data is instantly processed and recorded in your inventory system. This efficiency keeps your inventory up to date in real time, which is key for maintaining exact stock counts and prompt order fulfillment.

Improve accuracy

Barcode scanners automate capturing and recording data, significantly reducing the chances of common issues like typos, misreads, and transposition errors. This automation leads to fewer discrepancies in stock levels, enabling more accurate financial reporting and improved inventory forecasting.

Enhance customer service

Fast and accurate inventory management translates into better customer service. With barcode scanners, you quickly check stock availability and process transactions. Streamlining these tasks reduces wait times and improves the overall shopping experience. This efficiency helps you maintain customer satisfaction, shopper loyalty, and your reputation as a reliable and trustworthy seller.

Optimize your operations

A barcode inventory system streamlines various inventory tasks, from receiving shipments to tracking product movement within your warehouse. This optimization reduces the time and effort required for inventory management. Now, your team has more time to focus on other key aspects of your business.

Support inventory data analysis

The accurate and timely data barcode scanners capture helps you analyze inventory trends and generate insightful reports. This capability allows you to identify sales patterns, monitor stock performance, and make informed decisions based on real-time data.

4 Ways To Use A Barcode Scanner For Inventory Management

Streamline receiving product inventory

Take new inventory out of the box and put it right into your inventory management system. When new shipments come in, scan each product’s barcode and instantly update your records.

For example, let’s say you own a clothing store. When a shipment of new apparel arrives, your employees will use barcode scanners to quickly verify each item’s size, color, and quantity against the purchase order. This ensures all products are accurately logged into the barcode inventory system, reducing human error and making stock management seamless.

Reorder new products

Barcode scanners are handy for keeping track of inventory so you always know when it’s time to reorder. Scan a product, and the barcode inventory system instantly shows how much you have left. For instance, in a craft store, if you’re tracking inventory for popular items such as paint and brushes, scanning a barcode might show that your acrylic paint is running low.

When a product reaches a certain reorder level, the inventory system automatically generates an order form based on the product’s barcode. This way, you avoid running out of stock and keep your customers happy without any hiccups.

Reorder On Repeat With Thrive Inventory

With Thrive Inventory you can bring together all of your different sales channels into our software making stock level management easy. With minimum and maximum stock levels, you’ll know exactly what’s happening with all of your products at any set point in time, even if they are sold on different channels.

Manage cycle counts and physical inventory counts

Whether you’re doing them weekly or every couple of months, cycle counts are often time-consuming and tedious. Barcode scanners make the process much quicker and easier. Instead of manually counting items and entering everything by hand, you scan each product and the system instantly updates with the correct stock levels.

Power Up

Discover why cycle counts should be a regular part of your business, plus a free stock count template.

Let’s say employees in a home goods store use barcode scanners during their weekly count of kitchen appliances and decor. As each item is scanned, the system automatically checks for any discrepancies, making it easy to spot errors right away and keep inventory records up to date.

Create a faster checkout process

Barcode scanners help you keep checkout lines moving, which results in happier customers. Cashiers scan products and ring them up instantly, with no need to notate and calculate sales by hand.

Scanning books at a bookstore counter, for instance, speeds up the process and ensures any sales or discounts are applied immediately, making the whole experience faster and smoother for everyone. It also opens the possibility of completing transactions throughout the store instead of customers waiting in line.

Why Your POS Barcode Scanner Isn’t Enough

Your POS system’s barcode scanner is great for transactions, but it’s not equipped to handle the full scope of inventory management. For example, if you’re running a furniture store with a sales floor and a separate warehouse, the checkout scanner will only update stock levels of items you sell. It won’t track inventory changes in your warehouse. If you move nightstands between multiple locations or add coffee tables to Section B of the warehouse, you risk not having full visibility into your stock levels.

Additionally, using your POS barcode scanner to complete simple inventory management tasks, such as daily item counts, uses up valuable POS resources. If your POS barcode scanner is limited to a certain number of inventory counts, you may not be able to get a completely accurate tally, unless you’re willing to spend more for an upgrade. There’s also the possibility that your POS barcode scanner won’t integrate with your inventory management system. If the two systems don’t automatically connect, you’ll have to do additional manual entry to keep your records accurate.

External barcode scanners bypass these limitations. They’re also significantly more affordable than purchasing additional POS terminals. Simply keep a few on hand and charged, so you’re easily able to complete stock counting without interfering with ongoing POS transactions.

Tips For Easy Barcode Scanner Inventory Management

Use a barcode generator

The Newsletter For Small Businesses

Weekly expert insights, industry trends, and inspiring stories designed to help you run your business with confidence.

The Only Inventory System That Actually Helps You Run A Healthy Business

Thousands of customers all over the world use Thrive Inventory to run a healthy business.

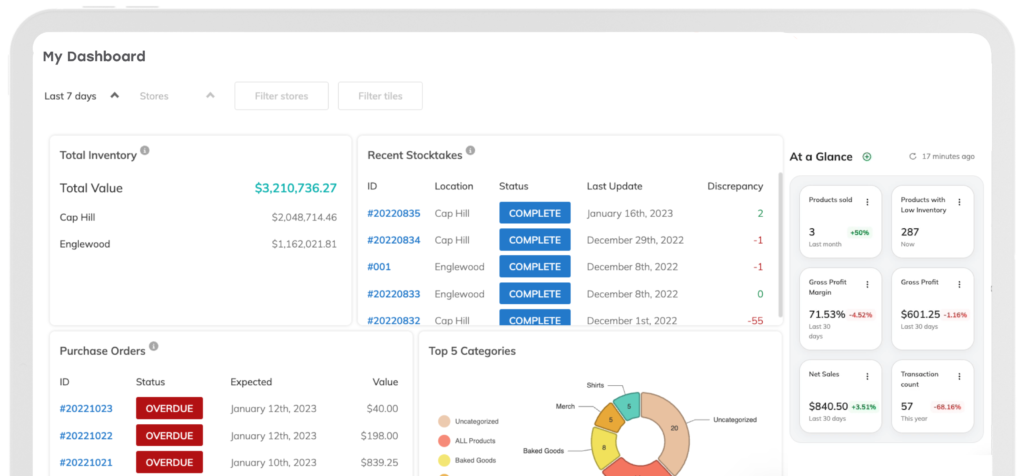

Thrive Inventory gives you control over all your inventory, sales channels, and metrics, allowing you to make the right decisions at the right time.

Make your life easier by using a barcode generator to create custom barcodes for your products. This tool designs and prints the scannable codes that your scanner software reads. Depending on your needs, choose from online generators for a quick and simple solution, or opt for advanced software if you require more customization.

Choose an inventory management system that fits your business needs

Make sure your inventory management software works well with the scanner of your choice and matches what your business needs. If you run a small gift store, for example, look for a system that’s easy to use and doesn’t require a lot of setup, as the information you’re collecting and tracking is relatively basic. If you own a specialty shop, such as a bakery or coffee shop, you’ll need a system with more advanced features like expiration date tracking and quick restocking options.

Connect Your Barcode Scanner To Thrive Inventory

Set your inventory team up for success by using a barcode scanner to simplify purchase orders, stock counts, invoicing, and internal transfers.

Train your staff

Your employees will use the scanners on a daily basis, so it’s a good idea to invest time in proper training. Show your staff how to correctly scan barcodes and handle common issues like misreads. You should also teach them how to navigate the barcode inventory management system. This includes adding new items, updating stock levels, and managing returns or adjustments.

Conduct regular quality checks

Don’t forget to schedule some time to review and verify your inventory data. This way, you ensure your scanners are working properly and are recording information accurately. Compare your scanned inventory with what’s actually on the shelves so you catch any discrepancies early and can make necessary adjustments.

The Best Barcode Scanners

Inateck Bluetooth Scanner

- Price: $69.99

- Top features: Compatible with multiple systems; can scan defective 1D barcodes; edit SKU prefixes from the scanner

The Inateck Bluetooth Barcode Scanner is a great option for retail stores that want to simplify their inventory management. It only takes a few seconds to set up and is compatible with various devices, operating systems, and POS systems.

One of the best parts about this scanner is its ability to quickly read all kinds of 1D barcodes, even if they’re blurry, damaged, or scanned in low light. The scanner also gives you the option to edit SKU prefixes or suffixes of up to 32 digits and even hide parts of a barcode if needed. It stores results directly in the inventory scanner and keeps track of counts, making barcode inventory management a breeze.

SocketScan S700 Scanner

- Price: $253.03

- Top features: Compatible with numerous POS systems; user-friendly design; quick and accurate data transfer; integrations with over 700 apps

The SocketScan S700 is a 1D barcode scanner that’s built for versatility, easily scanning both paper and screen barcode labels. Priced at around $250 depending on the vendor, the SocketScan S700 offers native support for Square POS and is fully compatible with other systems such as Shopify, Vend, and LightSpeed POS.

This scanner features bright colors and easy-to-read light icons. Beyond its basic functionality, the S700 scanner integrates with more than 700 applications and allows for fast and reliable data transfer over Bluetooth. This added layer of connectivity streamlines your inventory management and keeps your business processes running smoothly.

SocketScan S740 with Charging Dock

- Price: $330.41

- Top features: Capable of 1D and 2D barcode scanning; ideal for products that require age verification; compatible with multiple devices and operating systems

Also equipped with Bluetooth, the SocketScan S740 easily connects to various devices, including smartphones, tablets, and computers, across all major operating systems. This scanner comes with a charging dock and costs around $360, depending on the vendor.

Unlike the Inateck and the S700 scanners, the S740 scanner handles both 1D and 2D barcodes. This capability makes it highly effective for tracking a wide range of products. It also makes it a great fit for your business if you sell products such as alcohol or tobacco and need to verify customer age. This all in one solution lets employees check IDs and handle transactions with a single scanner, cutting down on the number of gadgets needed at checkout.

Adding A Barcode Scanner To Your Inventory Toolkit

There’s a lot more to barcode scanners than ringing up products at checkout. Their functionality creates a faster, more accurate inventory management process. When picking out a barcode scanner, think about the types of barcodes your products use and the price point and any specific features that make the most sense for your business. While this gadget is small, choosing the right one will save you tons of time, cut down on errors, and make your inventory management a whole lot smoother.

Keep Reading

The Newsletter For Small Businesses

Weekly expert insights, industry trends, and inspiring stories designed to help you run your business with confidence.

Try Thrive Inventory For Free

Add Thrive Inventory to your business and maximize your potential. With powerful and easy-to-use products, it’s time to take control of

your business and see what you can do with Thrive.