The Essential Guide To Completing Your 2025 Year End Physical Inventory Count

The end of the year is a whirlwind for small business owners, between holiday rushes, wrapping up sales, and planning ahead, it can feel like there’s no time to pause. But what if the key to entering the new year with confidence lies in one crucial, yet often overlooked, task?

Performing a thorough, accurate inventory count helps you close 2025 with confidence in your financial records, spot issues, and get organized for a successful new year. This guide breaks down what a year-end inventory count is, why it matters, and how you can complete it step-by-step.

Comprehensive email marketing efforts help you grow your business at every stage. No matter what industry you’re in, there are email campaigns that every small business needs to prioritize. Get the most out of every campaign with our expert tips.

What You'll Learn In This Blog

- What is a year-end inventory count?

- Why is a year-end physical inventory count important?

- Preparing for your end of year count

- How to conduct a physical year-end count by hand, step-by-step

- Why you should consider using inventory management software for your count

- How to automate your physical year-end count with thrive inventory

- Tips for a successful year-end inventory count

- Common challenges during year-end counts and how to overcome them

What Is A Year-End Inventory Count?

A year-end inventory count is a full, physical count of all the products and materials you have on hand at the end of your fiscal year. Unlike cycle counts, where you audit parts of your inventory regularly, the year-end count is a comprehensive snapshot of your entire stock. This count ensures your records match reality and sets you up with accurate ending inventory data for taxes, audits, and year-end reporting.

Free End Of Year Kit

After holiday sales, full inventory stock counts, and calculating your ending inventory, it’s enough to keep a small business owner up at night! That’s why we built the guides and tools you need to navigate the end of the year with confidence.

When should you complete your end of year inventory count?

The timing of your year-end inventory count can vary depending on your business needs and operations. Some small businesses prefer to conduct their physical count in December, right before the year closes, to get a precise snapshot for tax reporting and financial records.

Other businesses opt to do the count in January, after the holiday rush has ended and stock levels have stabilized. This timing can reduce pressure during busy sales periods and allow for a focused, distraction-free count.

Your accountant or financial advisor’s preferences may also guide the choice based on tax reporting schedules and requirements. Whichever timing you choose, prioritize accuracy and clear communication across your team for the best results.

Why Is A Year-End Physical Inventory Count Important?

A year-end inventory count plays a pivotal role in both the accuracy of your financial health and the operational efficiency of your business. Here’s why it’s so crucial:

Ensures accurate financial reporting and tax compliance

Physical counts ensure you have accurate inventory records that match what is on your shelves and back office, which directly influences your business’s financial statements. Ending inventory figures are required by accounting standards (GAAP) and tax authorities, ensuring you report correct profits, losses, and the value of your assets.

Power Up

Understanding how to calculate your ending inventory is essential for accurate financial reporting and effective business management. Visit our detailed guide to learn the key formula and practical tips to ensure your year-end inventory valuation is precise and reliable.

Detects discrepancies and shrinkage

Throughout daily operations, inventory can become inaccurate due to various reasons. A physical count helps identify these discrepancies:

- Products are in the wrong location

- Products have unclear, misprinted, or repeated labels

- Human error

- Software error

- Inefficient workflows or operations

- Insufficient product storage

Recognizing shrinkage and obsolescence allows you to take corrective action before it impacts your bottom line.

Improves inventory management processes

A comprehensive count isn’t just about numbers; it’s a tool to evaluate your current inventory procedures. It helps uncover weaknesses such as inefficient workflows, inaccurate recordkeeping, or storage problems. These insights enable you to improve your SOPs, optimize stock levels, and streamline your supply chain.

Supports better demand forecasting and purchasing decisions

Knowing the actual physical count and condition of your stock enables smarter planning for the upcoming year. You can identify slow-moving products, adjust reorder points, and plan promotions for aging inventory, ultimately reducing excess stock and improving cash flow.

Power Up

Explore our comprehensive guide to learn how forecasting customer demand can help you streamline inventory management and improve business performance.

Preparing For Your End Of Year Count

Planning ahead of time for your year-end inventory count is essential to ensure accuracy and efficiency. Here are key steps to get ready:

- Set a counting date: Choose a date for your annual inventory count, ideally outside of busy sales hours, to minimize disruptions.

- Notify and assign roles: Inform your staff well in advance. Assign clear roles such as counters (who physically count items), spot checkers (who verify counts), and recorders (who approve results).

- Organize your space: Clean and declutter your stock areas. Group similar items together and label shelves clearly to streamline counting.

- Gather tools: Prepare all necessary tools, including an updated stock list or inventory reports, barcode scanners, clipboards, pens, or your inventory management system needed for recording counts.

- Conduct a practice count: Host a dry run with your team on a small section of inventory to train staff, spot potential issues, and refine counting procedures.

- Document procedures: Have a clear, written physical inventory counting plan and protocols for recounts, reconciliation, and investigation of discrepancies.

How To Conduct A Physical Year-End Count By Hand, Step-By-Step

1. Start with clean records

Starting with clean records provides a reliable baseline and eliminates errors caused by outdated data. Before you begin your inventory count, ensure your database is accurate and up to date. This means confirming that your last product deliveries have been fully received and recorded in your system. Remove any obsolete or discontinued products from your inventory list to avoid confusion during counting.

2. Print your inventory spreadsheet

Generate and print an inventory spreadsheet or count sheets containing all products you will be counting. This document guides your counters and serves as a record for quantities counted. Ensure the list reflects current product SKUs, categories, and storage locations for efficiency and clarity during the count. We recommend creating different spreadsheets with only the products each person is responsible for to avoid confusion.

Free Template

Stay organized and increase the accuracy of your next stock count with our free printable and digital worksheet.

3. Count each item, comparing against your records

Count inventory one by one, marking quantities on your inventory sheets. Where possible, count in teams, each person counting the stock, then comparing before they record. Double-count products where there is a discrepancy between the two counters to reduce errors. Compare the physical counts immediately with the quantities on your spreadsheet or existing records, noting any discrepancies.

4. Reconcile and record results

After the counting phase, review the differences between the physical counts and your inventory system records. Investigate any major discrepancies by checking for misplaced products, possible theft, or labeling errors. Update your POS or e-commerce inventory records to reflect the accurate on-hand quantities derived from your physical count. Finally, archive all count records and reconciliation notes for future reference and auditing purposes.

Why You Should Consider Using Inventory Management Software For Your Count

Even if you’ve always handled the inventory counting process with pen and paper, using an automated management system can dramatically reduce stress and improve accuracy. Instead of relying on scribbled notes, manual data entry, and back-and-forth spreadsheets, software captures counts in real time.

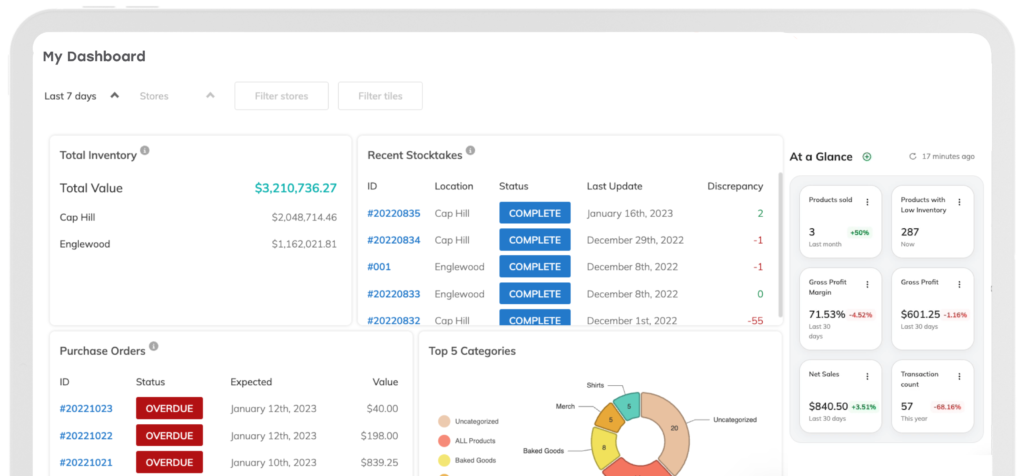

Inventory management systems like Thrive Inventory standardize your process and create a clear audit trail you can trust. It also sets you up to move seamlessly from a one-time year-end count into better day-to-day inventory control for the year ahead.

Here are some of the biggest benefits:

- Reduce errors: Scanning barcodes and entering directly into your system cuts down on fraudulent counts, typos, and lost sheets, so you’re not chasing avoidable mistakes later.

- Increase accuracy: Real-time validation and built-in product data (SKUs, variants, locations) help your team count the right item, in the right place, with the right units.

- Speed up the process: Digital counts move faster than manual tally marks, especially when multiple team members can work in the same system at once without duplicating effort.

- Add approval and accountability: Permission-based workflows and review/approval steps create a clear chain of responsibility, making it easy to see who counted, who checked, and what changed.

- Automatically sync to your sales channels: Once the count is finalized, your updated quantities update directly to your POS and e-commerce channels, reducing overselling, stockouts, and manual updates.

- Increase transparency with reporting: Detailed discrepancy and adjustment reports help you understand where you have inventory shrinkage, which products need attention, and how your accuracy improves over time.

Complete Your Physical Inventory Count With A Thrive Inventory Free Trial

Ready to say goodbye to manual inventory counting headaches? Try Thrive Inventory free for 14 days.

How To Automate Your Physical Year-End Count With Thrive Inventory

Conducting physical inventory counts can feel overwhelming when juggling multiple spreadsheets and handwritten notes. Using Thrive Inventory to automate this process makes it a lot more manageable.

Your team can follow a clear, straightforward process in one place, keeping everything organized, capturing important details, and syncing updates automatically across all your sales channels. Here’s a simple walk-through of how it works from start to finish.

1. Start with clean records

Starting with clean records provides a reliable baseline and eliminates errors caused by outdated data. Before you begin your inventory count, ensure your database is accurate and up to date. This means confirming that your last product deliveries have been fully received and recorded in your system. Remove any obsolete or discontinued products from your inventory list to avoid confusion during counting.

2. Create a Stocktake report in Thrive Inventory

Next, you’ll build the framework for your inventory cycle count.

- Create a new Stocktake report in Thrive Inventory and decide what you want to include: your entire catalog or specific locations, vendors, product categories, or raw materials.

- Pro tip: Build separate Stocktake reports for all your two person teams (for example, front-of-store, backroom, warehouse, or by category) so multiple team members can count in parallel.

- Manually pre-load each Stocktake report with the products you want to count, using filters like categories, vendors, or tags to keep things organized.

- Turn on “blind counts” if you want counters to enter what they see on the shelf without seeing the expected quantity or discrepancy column, which helps avoid bias.

3. Count your products

Once your Stocktake report is ready, your team can start the physical inventory count process.

With a barcode scanner

- Connect a compatible barcode scanner to Thrive Inventory.

- Scan each item’s barcode; every valid SKU scan will automatically add one unit to that product’s “Actual” quantity in the Stocktake.

- If you know the quantity in front of you, you can scan once and then adjust the number manually for faster entry.

Without a barcode scanner

- Use the Stocktake report as your digital count sheet.

- Manually count items on the shelf and type those totals into the “Actual” column for each product.

Add notes where needed (for example, damaged items, suspected theft, or mislabels) so reviewers have context.

Power Up

Discover our expert-reviewed guide to find the best barcode scanner tailored for your small business needs and streamline your operations today.

4. Submit your year end inventory count for approval

When the initial count is complete, it goes through an approval step to ensure accuracy and accountability.

- Only users in Thrive Inventory with the appropriate permissions (such as “Manage Stocktakes”) will see the option to approve and submit the final counts.

- Once submitted and approved, Thrive Inventory will update your on-hand quantities based on the Stocktake results.

- If something looks off, approvers can “Request Modifications,” send the count back, and leave notes asking the counter to recheck specific products, locations, or discrepancies.

5. Sync counts to sales channels

No more manually updating stock counts one by one in your POS or e-commerce system. Thrive Inventory instantly pushes out the right stock levels to the relevant sales channels and locations you selected. This reduces the risk of overselling, stockouts, and mismatched numbers between systems, giving you a single source of truth going into the new year.

6. View reporting

Finally, use Thrive Inventory’s reporting suite to understand the impact of your year-end count and tighten up your business operations.

- Stocktake Discrepancy Report: See exactly how your counts uncovered inventory discrepancies, units added or removed, the value of those changes, and where losses or gains occurred. You can enable Stocktake Notes, Product Notes, and other fields to give context to each adjustment.

- Due for Stocktake Report: Use this report to verify that every product you intended to count at year-end was actually included and to plan future cycle counts for the coming year.

Automate Your Year-End Inventory Count With Thrive Inventory

As 2025 winds down, now’s the perfect time to see how Thrive Inventory can make your year-end count faster and more accurate. Stock count errors happen, and that’s why using the right tools to automate this process is a game-changer.

Tips For A Successful Year-End Inventory Count

- Make the counting process engaging and thank your team: Celebrate the effort your staff puts in. Positive reinforcement helps maintain morale and encourages careful, focused counting.

- Plan ahead and allow ample time for accuracy: Don’t rush your count. Schedule enough time to avoid pressure, which can lead to mistakes and fatigue.

- Value accuracy over speed; rushed counts often require redos: It’s better to take a little longer and get it right the first time than to speed through and have to recount or fix errors later.

Common Challenges During Year-End Counts And How To Overcome Them

- Failing to reconcile discrepancies: Always investigate any differences between your physical count and your records rather than ignoring or assuming them.

- Not updating all stock records: Make sure every product location and item counted is reflected in your system, including slow movers and raw materials.

- Overlooking items stored off-site or in backrooms: Don’t forget to track inventory kept outside your main sales floor; these often cause inaccurate totals.

- Attempting to count during open business hours without planning: Inventory counts require undivided attention and should not be rushed or interrupted by normal store operations.

Free End Of Year Checklist

Already feeling overwhelmed by the end of the year? We’ll take you through everything you need to do to close out 2025, step by step.

Wrapping Up 2025: Building Confidence With Accurate Inventory

As you wrap up your year end inventory count, remember that this is more than just a task on your to-do list; it’s an opportunity to gain clarity on your business’s health and set a strong foundation for the year ahead. Taking the time to do it thoughtfully and accurately provides you with the confidence to make smarter decisions.

With the right preparation, tools, and a little teamwork, you can transform your year end count from a daunting chore into a smooth, even rewarding experience that leads your business toward growth and success in the next year.

The Newsletter For Small Businesses

Weekly expert insights, industry trends, and inspiring stories designed to help you run your business with confidence.

The Only Inventory System That Actually Helps You Run A Healthy Business

Thousands of customers all over the world use Thrive Inventory to run a healthy business.

Thrive Inventory gives you control over all your inventory, sales channels, and metrics, allowing you to make the right decisions at the right time.

Keep Reading

The Newsletter For Small Businesses

Weekly expert insights, industry trends, and inspiring stories designed to help you run your business with confidence.

Try Thrive Inventory For Free

Add Thrive Inventory to your business and maximize your potential. With powerful and easy-to-use products,

it’s time to take control of your business and see what you can do with Thrive Inventory.