Everything (And More) You Need To Know About Wholesale Inventory Management

Small businesses that sell wholesale face unique inventory challenges. From limited storage space to fluctuating demand to diverse product lines, it’s a lot of keep track of. Without a solid wholesale inventory strategy, these challenges can quickly become costly problems that most small businesses can’t afford in today’s competitive landscape. Let’s dive into the key benefits, best practices, and technologies that will help you master your wholesale business.

What Is Wholesale Inventory Management?

At its core, wholesale inventory management is efficiently controlling bulk product flows from your suppliers to customers. While this will look a little different for each wholesale business, these are some of the main processes you can expect to repeat on a daily basis:

- Determining your wholesale product assortment strategy

- Ordering bulk products and components from your vendors

- Receiving inventory into your back office or warehouse

- Tracking inventory and component stock counts for products you produce

- Syncing inventory across all your sales channels and locations

- Having enough product to fulfill customer demand

Power Up

Just getting started with adding wholesale to your business? Make sure to check out our comprehensive guide on Selling Wholesale To Retailers 101.

What is wholesale inventory management software?

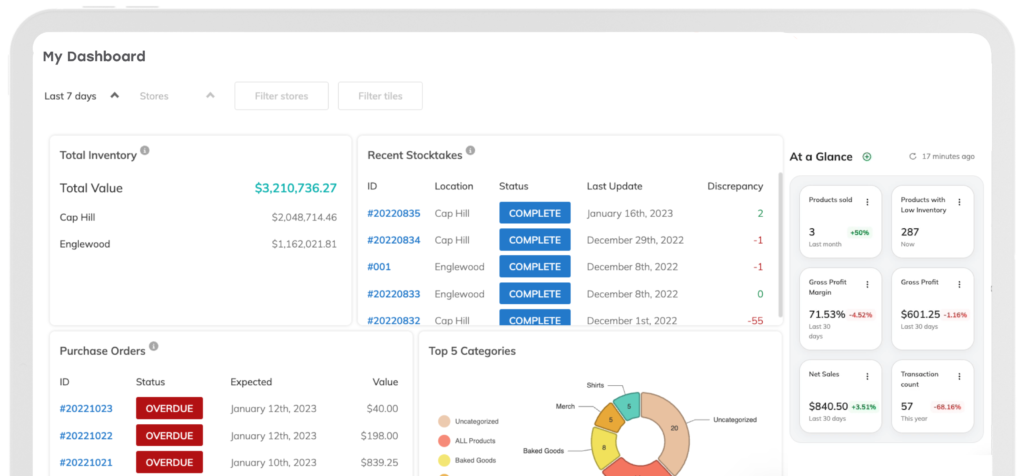

Wholesale inventory management software provides the exact tools you need to track every part of your inventory. It leverages automation and smart technology to inform decisions about the future of your business, eliminating manual spreadsheets, human error, and guesswork.

Your POS or e-commerce platform may have some built-in tools designed for getting started. However, a dedicated wholesale inventory management solution is essential for optimizing and scaling your business.

Run Your Wholesale Business On Repeat With Thrive Inventory

Keep accurate stock counts by syncing inventory levels across your wholesale business, sales channels, and/or storefronts. Centralize your stock and product catalog with one platform designed to increase efficiency.

Types of wholesale inventory

Production level inventory

If you produce your own wholesale products, you need to track raw material and work in progress (WIP) inventory. Your raw materials are the component-level inventory, such as ingredients or supplies. When you start turning your raw materials into your finished goods, they become WIP inventory.

Let’s take an artisan candle maker, for example. The wax blocks, glass holder, and essential oils are their raw materials. Once the wax is melted down and mixed with the essential oils in the holder, they are WIP inventory while it cures.

Finished goods

These are the products that you list in your catalog that are ready to be handed to customers. In the case of the candle maker, this is the finished candle that’s ready to burn.

Maintenance, repair, and overhaul (MRO)

In your wholesale business, this refers to all the equipment and supplies needed to sell products. A wax melter, barcode scanner, and cleaning supplies are examples you might find in the candle maker’s shop.

Benefits Of A Wholesale Inventory Management System

If you run a wholesale business, it’s definitely possible to still get products out the door without structured processes. However, effective wholesale inventory management allows you to confidently streamline and grow a healthy business.

Dial in on your cash flow

Your wholesale business is only making money if products are moving from the shelves to customers quickly. Any stock gathering dust in your warehouse is tying up profit and draining resources in holding costs.

By optimizing your inventory levels, you’ll have more revenue to invest in rather than it throwing away on warehousing, obsolete products, and handling expenses.

New inventory control and visibility

Once you implement a wholesale inventory software, you’ll view your business with a new clarity. At your fingertips, you can quickly view real-time inventory counts and centralized data across multiple sales channels.

This empowers you to correct workflow inefficiencies, reduce excess inventory and stockouts, while trusting your backend data. Basically, you’ll spend less time on manual tasks and fixing mistakes. That means more time connecting with customers and planning the future of your business.

Focus on world-class customer experience

In today’s competitive wholesale market, delivering an exceptional customer experience is no longer a nicety but a necessity. By prioritizing customer satisfaction, wholesale businesses can differentiate themselves from competitors and build strong relationships that lead to long-term partnerships.

Effective inventory management plays a key role in this strategy. Having the right products that your customers are asking for available and on time enhances trust and relationships.

Power Up

Once your wholesale inventory is running like clockwork, it’s time to expand. Here are 7 winning ways to successfully grow.

4 Wholesale Inventory Management Processes

1. First-in, first-out (FIFO)

FIFO means the oldest inventory items are sold or used first. This is especially important for wholesalers working with products with an expiration date, such as food, CBD, and cosmetics. Additionally, by aligning stock rotation with financial reporting, FIFO provides the most accurate cost tracking and higher reported profits. This matters during inflationary periods, as older, lower-cost inventory is recorded as sold first.

For example, you sell hot sauce and are expecting a big order of 150 bottles to come through before Super Bowl Sunday. You received a batch of 100 bottles on January 4th and another set of 100 on January 24th. To fulfill the order for your customer, you’ll package all of the bottles from the January 4th shipment first, then 50 bottles from the January 24th shipment.

2. Just-in-time (JIT)

JIT inventory management aligns raw material orders and production schedules with actual customer demand. This may be beneficial for your business as it minimizes excess stock and reduces warehouse management costs. While JIT lowers holding costs and optimizes cash flow, it requires precise coordination to mitigate risks from supply chain disruptions or sudden demand spikes.

Let’s break it down. If you make and sell wooden puzzles, you’ll have the necessary raw materials to start a product, but you don’t have piles of finished puzzles on your warehouse shelves. When your retail customer places an order for 10 mountain puzzles and 10 lion puzzles, you’ll build that exact amount and send them off to your customer.

3. Bill of material tracking

If you produce your own products, bill of material tracking will manage your raw material and WIP inventory. This approach ensures your material costs and component inventory levels are calculated in real time during production rather than post-sale, giving you precise control over your supply chain. By integrating your bill of materials inventory with your production workflow, you can proactively re-order and schedule production to meet demand efficiently.

The process the candle maker used in our example above is a great use of bill of material inventory management. The inventory levels for the wax blocks and essential oils will decrease as the candle is being made, and the finished candle inventory will automatically increase when it’s ready for sale.

4. Product bundling

Product bundling is a powerful wholesale strategy when combining items sold individually and as part of a bundled offering. For example, a skincare business can create a product bundle of their three seasonal spring scented lotions. This requires dual inventory tracking to manage stock levels for both standalone products and finished bundles across multiple sales channels.

Leveraging Technology With Wholesale Inventory Management Software

Sales channel syncing and centralization

If you sell wholesale and also have your own storefront or e-commerce store, inventory tracking can get complicated fast. Knowing exactly where all your products are and controlling profitability is only possible with the right inventory management software.

A wholesale system with internal transfers is helpful for businesses with multiple locations or multiple warehouses. That way, no matter where you or your team is located, you have visibility into inventory levels in real time.

Wholesale variant tools are important for setting different prices for your wholesale customers and your retail customers. It’s also essential to track sales for each channel. For instance, let’s say your greeting card line sells really well at your storefront but barely budges with your wholesale customers. That means maybe your products have more competition there or aren’t reaching the right audience. So instead, you take your greeting cards off your wholesale catalog and add a new poster design to capitalize on those high sales.

Invoicing

An invoicing software for wholesale inventory is critical for placing, tracking, and fulfilling orders. By automatically adjusting stock levels for each sale, you prevent costly errors like overstocking or stockouts that disrupt operations.

What’s equally as important is the documentation it provides. Automated invoicing reduces human errors in inventory records and customer orders, minimizing discrepancies that often lead to financial losses or compliance challenges during audits.

Inventory reporting

Detailed inventory reporting is a cornerstone of successful wholesale management, providing the insights needed to keep stock levels balanced and operations running smoothly. By analyzing key reports, wholesalers can make informed decisions that boost profitability and customer satisfaction. Here are the top three wholesale inventory reports we recommend looking at daily:

Inventory valuation

An inventory valuation report gives you a real-time snapshot of the total cost of sellable products, raw materials, and WIP inventory. This data shows your potential profits and what products are tying up cash flow.

For instance, let’s say you have $3,000 worth of red leather leftover from a skirt you sold during the holiday season. Leverage it to make a profit instead of sitting on the shelf by designing a red leather handbag that you market and price as a limited edition product.

Stock forecasting

This report is as close as it gets to having a magic ball that tells you the estimated timeframe before a product sells out. By using historical sales data and market trends to predict future demand, you have the information you need to keep optimal stock levels. This minimizes over and understocking, while putting customer satisfaction at the forefront by always having the products your shoppers are looking for.

Turnover ratio

The turnover ratio report is essential for dialing in your product assortment and marketing strategy. Basically, it reveals how efficiently inventory is sold and replaced. This helps wholesalers identify slow-moving items, adjust pricing strategies, and optimize storage costs to maintain healthy profit margins.

If you can barely keep your miso sesame chocolate bar on the shelves, consider expanding that line to include miso sesame chocolate-covered pretzels and brown butter miso chocolate cookies.

Cycle counts

Wholesale businesses have a lot of moving parts, especially if you sell on multiple sales channels. No matter how much you automate, it’s likely you can’t keep track of everything or completely eliminate human error. Cycle counts are the best way to manage inventory levels. By counting your inventory in small increments, you can ensure that what you have in your warehouse matches your digital records.

Wholesale cycle count best practices

- Count your highest value and most popular products regularly, whether it’s daily, weekly, or biweekly.

- Use a barcode scanner to increase accuracy and automatically update your inventory management system.

- Assign different team members to different product categories to spread out responsibility.

- Have two employees complete a section together and require a manager’s approval before updating your stock levels.

Supply chain management

As a wholesaler, you’re essentially the middleman between vendors and your customers. That means your supply chain management processes can truly make or break your business. Inventory management tools, like alerts and purchase orders, not only prevent costly stockouts and overstocking but provide instant visibility into inventory levels and order status. This workflow enables faster, data-driven purchasing decisions.

Set custom alerts when a product reaches its minimum reorder level and use automatic purchase orders to easily build your next order with the exact products and amounts you need. These technologies enhance collaboration with suppliers, simplify reordering, and are proactive rather than reactive, minimizing disruptions and supporting continuous operations.

Run Your Wholesale Business On Repeat With Thrive Inventory

Keep accurate stock counts by syncing inventory levels across your wholesale business, sales channels, and/or storefronts. Centralize your stock and product catalog with one platform designed to increase efficiency.

Two Real Companies That Found Success Using Thrive's Inventory Management Software For Wholesale

Stone's Beer And Beverage Market

Growth often brings uncertainty, but for Nick Wendowski, owner of Stone’s Beer & Beverage Market, external challenges became a catalyst for transformation rather than a setback. When faced with the need to temporarily relocate his retail operation, Nick seized the opportunity to overhaul internal processes and prepare for future expansion.

During this transitional period, he not only streamlined operations but also launched and rapidly grew a wholesale business—from zero to 150 accounts in just two years—to offset lost retail revenue. “We knew we had to pivot and find a new revenue stream, and wholesale was the natural next step,” Nick shares. “Despite the intense competition, we carved out a niche by staying small and agile, which allowed us to adapt quickly and serve our customers better.”

None of this would have been possible for Nick without Thrive’s inventory management system. Since Thrive Inventory syncs catalogs, stock levels, and reporting across all his sales channels, it made expanding to wholesale seamless and accessible for the Stone’s team so they could quickly diversify sales.

Power Up

Nick shares Stone’s Beer & Beverage Market’s wholesale playplay on The Power Up Podcast.

Saratoga Olive Oil

A year after opening their first storefront, Saratoga Olive Oil was named one of the top five stores in the world for their product selection from the Olive Oil Times. They immediately experienced a growth spurt and began bottling themselves to their storefronts and wholesale customers.

But managing production batches by hand wasn’t cutting it, and they needed a much better process for their manufacturing operations. That’s when they switched to Thrive Inventory’s bill of material tools from Katana to deduct ingredient and material stock levels at the time of creation.

With better production and inventory control, the team at Saratoga Olive Oil feels confident in scaling their wholesale business. Blair, the National Sales Operations Manager, shares, “We switched from Katana to Thrive Inventory, and it was the best decision we have ever made. The amount of features we will be able to use, as well as the ease of use is great.”

Power Up

Discover how Saratoga Olive Oil saves thousands of dollars with Thrive Inventory’s Bill of Materials tools for their wholesale customers.

Moving Forward: Mastering Wholesale Inventory For Sustainable Growth

Wholesale inventory management is more than keeping shelves stocked—it’s about building a resilient, efficient, and customer-focused business. By implementing these inventory control techniques and technologies, small wholesalers can minimize costs, boost cash flow, and deliver outstanding service that sets them apart from the competition. As you look to grow your wholesale business, remember that investing in smarter inventory management today will lay the foundation for long-term success and adaptability tomorrow.

The Newsletter For Small Businesses

Weekly expert insights, industry trends, and inspiring stories designed to help you run your business with confidence.

The Only Inventory System That Actually Helps You Run A Healthy Business

Thousands of customers all over the world use Thrive Inventory to run a healthy business.

Thrive Inventory gives you control over all your inventory, sales channels, and metrics, allowing you to make the right decisions at the right time.

Keep Reading

The Newsletter For Small Businesses

Weekly expert insights, industry trends, and inspiring stories designed to help you run your business with confidence.

Try Thrive Inventory For Free

Add Thrive Inventory to your business and maximize your potential. With powerful and easy-to-use products, it’s time to take control of your business and see what you can do with Thrive.